Recently, the Brand Africa 100 selected Anbessa brand among the top three admired African brands next to Nigeria’s Dangote and South Africa’s MTN Telecommunication Company.

After conducted survey in 23 countries, which cover all African economic regions and collectively represent at least 75 percent of the population and the GDP of Africa, the company becomes the most dominant brands across Africa, according to the press release sent to The Ethiopian Herald.

Obviously, this is a big success for Ethiopia; because, in the 21st century, the growth of each country’s economy is now mostly influenced by the assets based on physical or non-physical grounds.

That is why brand management has become a central construct that is not only debated in the marketing field but also in the economy and other social disciplines.

Globalization processes have given rise to the notion of global brands as attractive assets to countries, corporations, and their managers. Creating and selling international brands is the classic trick of industrialized nations.

As Ethiopia is striving to achieve structural economic transformation, its rising industries are expected to play a pivotal role. For the products of these industries to penetrate into the international market, it is a must that they have to be able to build a strong brand.

That is why the government has built several industrial parks so that renowned international brands come and invest in the country. In addition, local industries such as Anbessa Shoe Share Company have also managed to build and promote their brands internationally.

Anbessa Shoe is the oldest shoe manufacturing enterprise in Ethiopia. The company was established by an Italian expatriate in the 1930s. It obtained a measure of goodwill by the 1950s when it was known by the name DARMAR. The company introduced industrial machinery and availed shoes for men, women, and children. In the mid-1970s the manufacturing facilities were nationalized by the Derg regime.

The company was privatized again in 2012 and purchased by the current owner, Tedla Yizengaw. At the time of privatization, the company had 800 employees and was making significant losses. Now the company is profitable, has expanded its workforce to 1,140 and increased production as a result of restructuring, machinery upgrades and improvement in systems and production layout.

Anbessa’s manufacturing facility is located in Addis Ababa and has about 33 outlets locally. Its main products are leather shoes (casual, military and safety shoes), leather articles (bags, wallets, and belts) and outsole. It serves both the domestic and the export market. The company is a market leader, commanding approximately 65% to 70% of the local shoe retail business, according to the Investment Commission’s report.

The company also contributes significantly to the generation of foreign currency for the country by exporting shoes to different parts of the world such as USA, EU, Middle East, Asia, and Africa.

The company is on the verge of completing a manufacturing expansion project which will result in the current plant operations moving to a new site in the Akaki/Kaliti area. The new plant will be compliant with international best practice, thereby enhancing export potential.

It will also improve production efficiency, capacity, health and safety standards for staff. The new plant will enable the company to increase the production of Shoes from 3,500 pairs per day to 10,000 per day, Handbags from 20 to 120 pieces, Belts from 150 to 500 pieces per day.

With the anticipated increase in production capacity at the Akaki/Kaliti plant, the company is now looking to secure its supply of quality raw material (leather) by establishing a tannery in the northern part of Ethiopia – Bahir Dar City, Amhara Regional State.

The company has already secured land and hired a project manager for the project. As well, the project feasibility study is complete and the design of the factory is in progress.

Upon completion, it will supply finished leather and leather products for Shoe factories, Company Deputy General Manager, Taddese Gurmu said. It is designing, manufacturing and retailing trendy shoes that serve a multitude of purposes with the capacity of producing 4,500 pairs per day, employing resourceful skilled hands and installing state-of-the-art equipment to keep meet the demand.

He also added the company started expansion and diversification of its products with a vision of competing with the international markets.

The new plant enables the company to produce 10,000 pairs per day and export more than 80 percent of its product. It also has the capacity to employ more than 3,500 peoples.

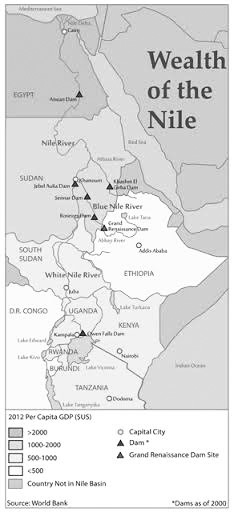

Anbessa currently has over 37 outlets and exports its products to Kenya, Uganda, South Sudan, Somaliland, and European countries. It came in at number three in the list of most admired African brands, according to Taddese.

Currently, tanneries in the country produce all forms of hides and skins and finished leather for the domestic and export markets. They supply the local leather goods industry which sells finished leather in the form of soles, shoe uppers, leather garments, stitched upholstery, backpacks, purses, and industrial gloves.

Domestic demand for leather and leather products is quite significant. According to the Ethiopian Leather Industry Development Institute (LIDI), demand for finished leather in 2015/16 is approximately 101.75 million square feet and is forecast to reach 282.11 million square feet by 2020/21.

Ethiopian skins have a good reputation in the international leather market for their unique natural qualities of fitness, cleanness, and compactness of texture, thickness, flexibility, and strength. The highland sheepskins, known as “Hair Sheep” are considered to be the world’s finest and have a highly compacted texture.

The Ethiopian Herald June 20/2019

BY GIRMACHEW GASHAW